Picking Tools

In order to facilitate the creation of a working environment around a vertical storage lift that is as good and efficient as possible, a number of picking tools are available. These enable the operator to quickly identify where on the load tray the item that is to be picked is located.

A pick display, laser pointer, or LED bar provides assistance when a load tray containing items appears in the handling opening. They not only make picking simpler, but also faster and more ergonomic, almost completely eliminating the risk of picking errors. Choose the picking tool that best meets the needs of your business, or why not try combining them to for the ultimate picking tool?

LED bar

The LED bar is made up of a number of LEDs that are placed in a row along the front edge of the handling opening. The diodes come on to mark the line from which an item is to be picked, and a number indicates the compartment in that line where the item is located. The LED bar is an efficient picking tool that works best if used in combination with a pick display. Information about incoming or outgoing deliveries, as well as up to date quantities prevent picking errors. In order for the LED bar to work as intended, the vertical storage lift must be controlled by a superordinate system, e.g. Compact Store or Compact Node.

| Designation | Item number |

| LED bar for Compact Lift 1220 | FLED-1220 |

| LED bar for Compact Lift 1830 | FLED-1830 |

| LED bar for Compact Lift 2440 | FLED-2440 |

| LED bar for Compact Lift 3050 | FLED-3050 |

| LED bar for Compact Lift 3660 | FLED-3660 |

| LED bar for Compact Lift 1220 with telescopic extension | FLEDHU-1220 |

| LED bar for Compact Lift 1830 with telescopic extension | FLEDHU-1830 |

| LED bar for Compact Lift 2440 with telescopic extension | FLEDHU-2440 |

| LED bar for Compact Lift 3050 with telescopic extension | FLEDHU-3050 |

| LED bar for Compact Lift 3660 with telescopic extension | FLEDHU-3660 |

| LED bar for Compact Twin/Double 1220 | FLEDKU-1220G23 |

| LED bar for Compact Twin/Double 1830 | FLEDKU-1830G23 |

| LED bar for Compact Twin/Double 2440 | FLEDKU-2440G23 |

| LED bar for Compact Twin/Double 3050 | FLEDKU-3050G23 |

| LED bar for Compact Twin/Double 3660 | FLEDKU-3660G23 |

Laser pointer

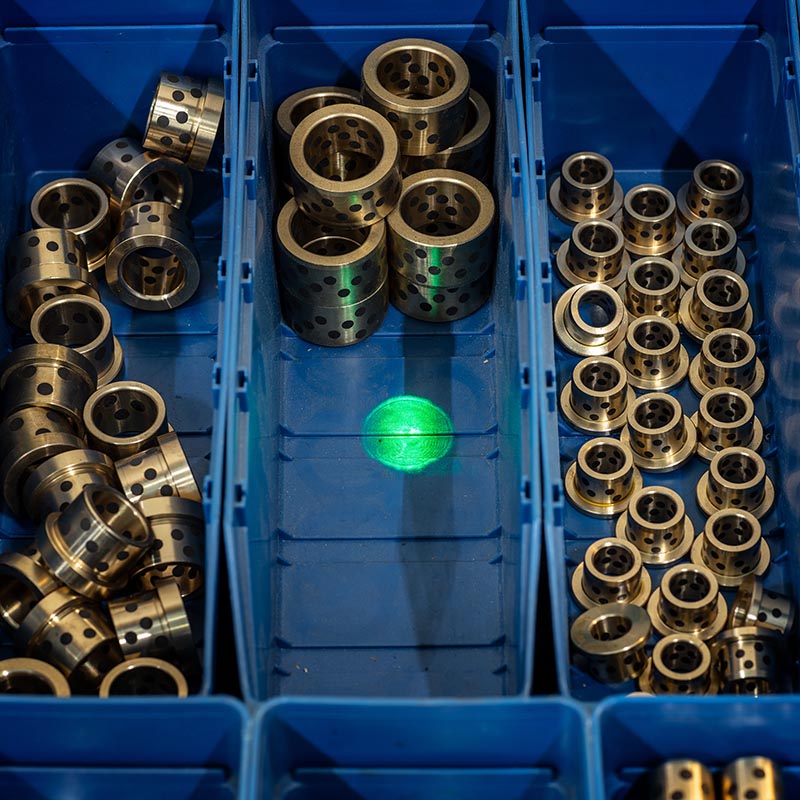

In instances where trays contain multiple compartments that hold small items, a laser pointer is an effective picking tool. A 50 mm cone of steady green laser points down into the compartment from which the next pick is to be made. The laser pointer works best in combination with a picking display that specifies incoming or outgoing deliveries and quantities, making picking errors almost impossible.

In order for the laser pointer to work, the vertical storage lift must be controlled by a superordinate system, e.g. Compact Store or Compact Node.

| Designation | Item number |

| Laser pointer 1220 | FLP-1220G22 |

| Laser pointer 1830 | FLP-1830G22 |

| Laser pointer 2440 | FLP-2440G22 |

| Laser pointer 3050 | FLP-3050G22 |

| Laser pointer 3660 | FLP-3660G22 |

Pick display

The pick display is a screen that, by means of an easy to read interface, shows the operator all necessary information pertaining to an order along with an overview of the load tray. Color coding specifies the position of the compartment from which the pick is to be made, minimizing picking errors. An arrow on the screen indicates where it is an incoming delivery, an outgoing delivery, or a stocktaking exercise.

The pick display is the most commonly used picking tool for Compact vertical storage lifts and may be enough on its own in instances where trays are split into larger compartments. It can also be combined with other picking tools in order to further facilitate work or in instances where trays have smaller and more numerous compartments.

| Designation | Item number |

| Pick display kpl. G2-3 | FDP-G2-3-CSF |

| Pick display kpl. G2-3 | FDP-G2-3-CT |

| Pick display kpl. G2-3 Opening 2 | FDP-G2-3-02-CSF |

| Pick display kpl. G2-3 Opening 2 | FDP-G2-3-02-CT |

| Pick display kpl. G2-3 Opening 3 | FDP-G2-3-03-CSF |

| Pick display kpl. G2-3 Opening 3 | FDP-G2-3-03-CT |

Label printers

Label printers are used for printing labels to mark parts, warehouse locations, and orders. Printing requires WMS or ERP control, and the printer can be easily connected to a computer via USB or wirelessly via Bluetooth. There are different printer models to choose from.

Scanners

Using a scanner that acknowledges components, storage locations, and orders increases the reliability of picking and stock control. There is both hand helded scanners and smaller finger scanners. The input model acts as a keyboard replacement and is used to scan in a PC dialog. The acknowledgment model is used to scan at a vertical storage lift or work table. It can be used for both put aways and take outs. It replaces the acknowledgment process previously done at the vertical storage lift. The scanner requires the control of software Compact Store, another WMS, or ERP.

Confirmation buttons

Picks are easily acknowledged by pressing one of the confirmation buttons located on the outer edges of the handling opening.

| Designation | Item number |

| Confirmation buttons | FKK |

| Confirmation buttons opening 2 | FKK-02 |

| Confirmation buttons opening 3 | FKK-03 |

Foot pedal

For large or heavy items that need to be lifted with both hands, the easiest way to acknowledge them is by using a foot pedal.

| Designation | Item number |

| Foot pedal Acknowledgment, 10 m cord | FFP-10M |